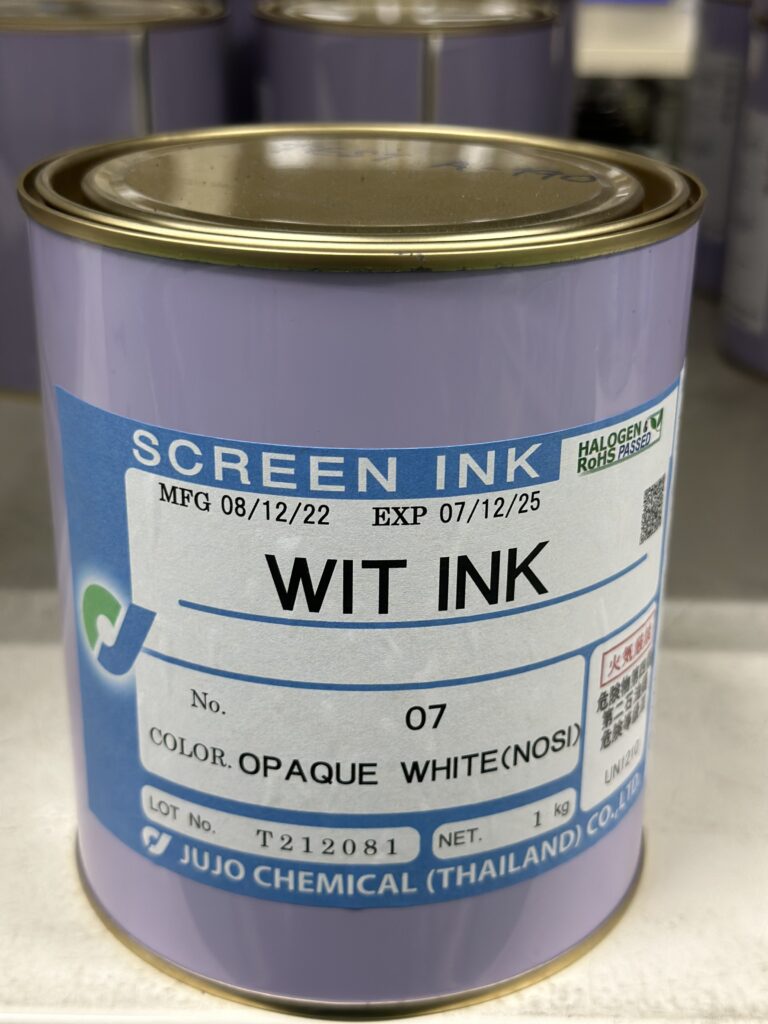

WIT INK

INTRODUCTIONS

WIT INK is one component of solvent based ink, developed to use Hydrographic or water transfer printing film such as a helmet. As a result of excellent flexibility, this ink can use without coating.

APPLICATIONS

Helmet of Motorcycle (ABS, PC)

* < Printing Process>

Print on transfer printing paper → dry fully → dip the transfer printing paper in the water →take the transfer printing paper out →transfer printing film to the material → remove water → drying

CHARACTERISTICS

- This can transfer printing without adhering level.

- Due to flexible film, ink can use without coating.

- Able to transfer printing to curve material.

- The properties of non- silicon type ink can good coating properly.

- Good gloss.

HOW TO USE

« STANDARD INK »

Dilute the ink with 10 -30 parts of PC THINNER (Fast Drying, Standard Drying, Slow Drying) before print. Use printing block about 100-200 meshes.

« OVERCOAT CLEAR »

Use CLEAR INK by dilute ink with 10 -30 parts of PC THINNER (Fast Drying, Standard Drying, Slow Drying) before print. Use printing block about 100-200 meshes.

DRYING

« PC STANDARD DRYING THINNER 15%, 250 Meshes »

40°c 5 minutes

POT LIFE

There is not pot life.

HOW TO WASH UP THE PRINTING BLOCK

Use VINYL CLEANING THINNER.

COLORS & TYPE OF PACKING

1 kg metal can.

PRECAUTIONS

* The information may be updated or changed without notice.